CASING STRUCTURE

There are two different casing types; the slide-in model and the modular model.

CS Slide-in casing version to be built into AHU. Casing for winded rotor 300-2450 mm diameter. Casing in one piece. No cover plates. Light sheet metal construction. Flexible dimensions to fit into AHU. Adjustable brush sealing. Fix Purge sector 5 Deg.There are adjustable brushsealing around the rotor periphery and along the middle beam.

Options: Purge sector adjustable 2.5°,5.0°, 10° *Powder coated sheet metal, *cover plates, *Drain pan, *Insulation and *SST 304 complete casing

CSD Slide-in casing version to be built into AHU. Casing for sectorized rotor up to 2400 mm diameter. Casing horizontally divided (for e.g difficult mounting conditions), delivered in two parts. Sectorized rotor not mounted. No side panels. Light sheet metal construction. Flexible dimensions to fit into AHU. There are adjustable brush sealing around the rotor periphery and along the middle beam. Fix Purge sector 5 Deg.

Options: Purge sector adjustable 2.5°,5.0°, 10° *Powder coated sheet metal, *cover plates, *Drain pan, *Insulation and *SST 304 complete casing

DS Slide-in casing version to be built into AHU. Casing for sectorized rotor Ø2451-5000 mm. The casing horizontally divided into two parts. The casing comprises an aluminum profile frame, or galvanized steel profile frame on units > Ø4250 mm. The frame profiles are joined without corners to provide a rigid, gap-free framework. Rotor suspension allows rotor adjustment. There is adjustable brush sealing around the rotor periphery and along the middle beam. The rotor segments are delivered in separate packaging. Parts delivered separately, unassembled. Fixed Purge sector 5 Deg.

Options: *Powder coated sheet metal, *cover plates, *Drain pan, *SST 304 complete casing

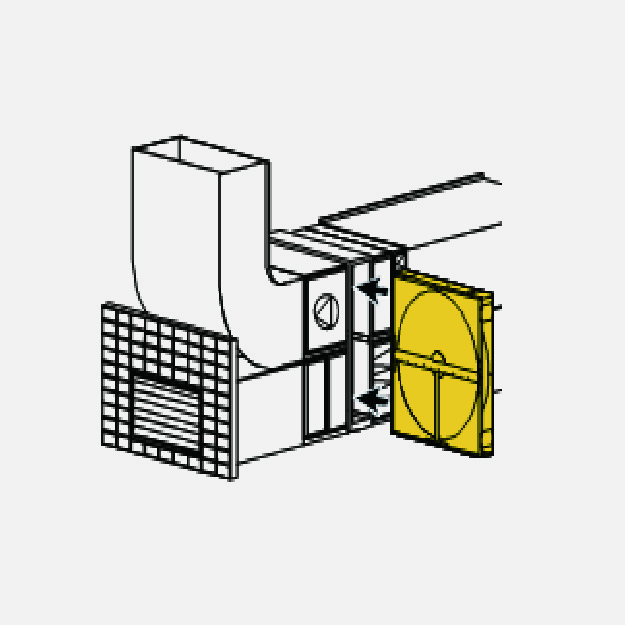

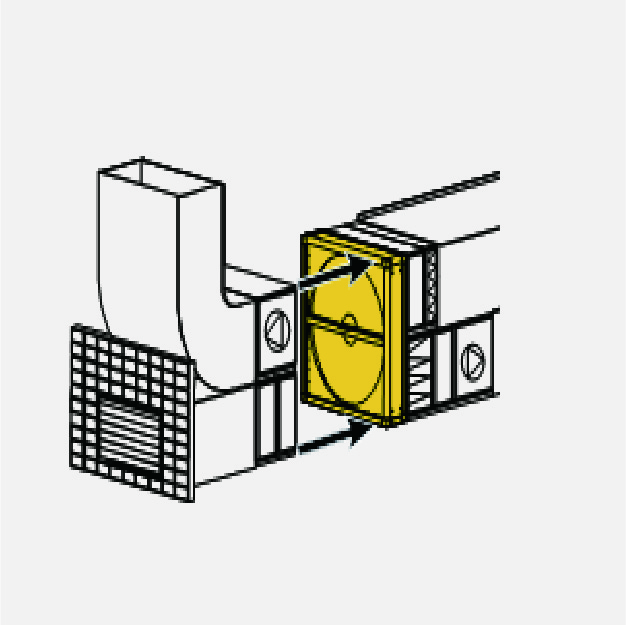

OCS Casing, universal casing to be used both as slide- in or as standalone casing, for direct connection to AHU or duct. The housing frame is made of heavy-gauge formed sheet metal with a rigid middle beam to prevent deflection created by the air stream. The “eccentric nut” connection of the rotor to the middle beam provides an easy adjustment of the rotor (on the X and Y axis) within the casing. Casing for winded rotor 801-2450 mm diameter. Casing delivered together with Winded rotors are delivered in one piece, Casing for Segmented rotor ø 801 – 2500 mm. casing delivered together with segmented rotors are delivered in 2 parts. Casings for ø 1000-2500 mm rotors are equipped with double “triangle inspection hatch”. The triangle inspection hatch provides limited access to the drive motor from both of the warm and cold side of the rotor unit. There are adjustable brushsealing around the rotor periphery and along the middle beam.

Options: *Purge sector, adjustable 2.5°-5.0°, 10° fixed. * cover plate removable at service side. *Powder coated, *Drain pan, *Insulation and *SST 304 complete casing

D Modular unit for sectorized rotors Ø2451-5000 mm. The casing horizontally divided into two parts. The casing comprises an aluminum profile frame, or galvanized steel profile frame on units > Ø4250 mm. The frame profiles are joined without corners to provide a rigid, gap-free framework. Rotor suspension allows rotor adjustment. There is adjustable brush sealing around the rotor periphery and along the middle beam. The casing is fitted with insulated panels and an inspection hatch. The rotor segments are delivered in separate packaging. Parts delivered separately, unassembled. Fixed Purge sector 5 Deg.

Options: *Powder coated sheet metal, *Drain pan, *SST 304 complete casing